Brunnen Schlagen: Mastering the Art of Well Drilling

Brunnen schlagen, or well drilling, is a crucial process for accessing groundwater. This article delves into the various aspects of well drilling, exploring techniques, equipment, and practical tips to ensure successful outcomes. Whether you’re a beginner or an experienced driller, understanding the fundamentals and best practices of brunnen schlagen can significantly impact your project’s success.

Understanding Brunnen Schlagen Techniques

The techniques used in brunnen schlagen can vary based on soil composition, location, and desired depth of the well. Traditional methods include percussion drilling and rotary drilling. **Percussion drilling** involves repeatedly dropping a heavy drill bit into the ground, creating fractures that allow for easier penetration. This technique is particularly effective in rocky terrain where a consistent drilling path is challenging.

Key Techniques in Well Drilling

Among the essential techniques in brunnen schlagen, rotary drilling stands out for its versatility. This method utilizes a rotating drill bit and is suitable for deeper wells. In contrast, **cable tool drilling** is a method where a chisel-like tool strikes the ground to break it apart and retrieve soil samples. Each technique has its pros and cons, which should be considered depending on the project requirements.

Choosing the Right Drilling Equipment

Having the right drilling equipment is vital for the success of any brunnen schlagen project. **Drill rigs**, drill bits, and water pumps are among the key pieces of equipment needed. For instance, a hydraulic drill rig can be efficient for large projects, while portable, manual options may be preferable for smaller endeavors. Proper equipment selection not only influences drilling efficiency but also the overall safety and quality of the well.

The Importance of Site Assessment

A comprehensive site assessment is critical before beginning any well drilling project. This process involves analyzing soil samples, understanding groundwater flow, and identifying potential contaminants. **Site assessment** can reveal vital information about the best locations for drilling and the type of equipment required, ultimately leading to more successful outcomes.

Soil Analysis Techniques

Conducting soil analysis forms a fundamental part of the site assessment. By taking soil samples from various depths, you can determine texture, composition, and permeability. This data is essential to understanding how much water can be extracted and the best drilling technique to employ. Tools such as augers can simplify this process significantly, allowing for precise and efficient sampling.

Hydrologic Modeling and Predictions

Hydrologic modeling enables drillers to predict groundwater behavior. Utilizing software to create models based on site data can help you visualize potential water flow and quality. Such predictions can inform the decision on where to drill and assist in planning for potential challenges, ultimately increasing the chances of project success.

Safety Considerations in Brunnen Schlagen

Safety is paramount in all phases of brunnen schlagen. Potential hazards include equipment malfunctions, unstable ground, and exposure to contaminated water. Developing a robust safety plan that encompasses these concerns will help protect drillers and ensure successful operations. Basic safety gear, including helmets, gloves, and protective eyewear, is essential for reducing risk during drilling efforts.

Emergency Preparedness Strategies

Being prepared for emergencies can save lives and minimize project disruptions. Establishing clear communication channels among the drilling team and creating an emergency response plan are crucial steps. Conduct regular training sessions that cover equipment usage and safety protocols to ensure all workers are prepared to handle unexpected situations effectively.

Regular Equipment Maintenance

Regular maintenance of drilling equipment is vital for safety and efficiency. Implementing a schedule for inspections and servicing can prevent breakdowns and ensure that all tools operate as designed. Keeping detailed records of maintenance helps identify patterns that could point to potential failures, allowing for proactive replacements and repairs as needed.

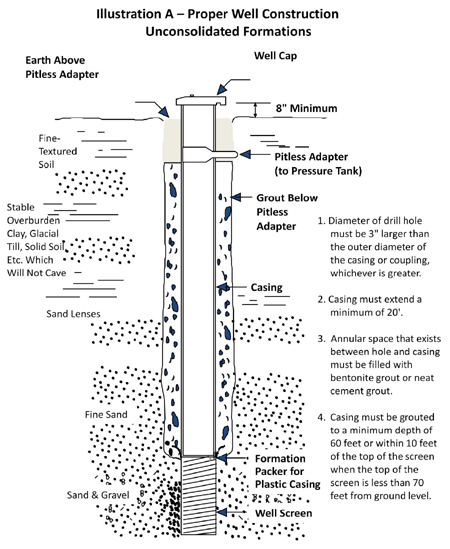

Permanent Well Installation and Maintenance

Once drilling is complete, installing a permanent well structure is the next critical step in the brunnen schlagen process. Proper casing and sealing ensure that the well remains functional and safe from contamination. Implementing maintenance strategies, including regular water quality testing and inspections, is fundamental for ensuring long-term success.

Well Casing Materials and Practices

Choosing the right casing materials influences the well’s durability. Steel and PVC are common materials used based on local regulations and groundwater quality. Ensuring proper installation of casing prevents collapse and contamination of the groundwater supply, making this step crucial in the overall brunnen schlagen process.

Long-term Maintenance Strategies

An effective maintenance strategy involves regular monitoring of water quality and flow levels. It’s advisable to conduct annual checks and perform necessary repairs promptly. A good understanding of common signs of deterioration, such as changes in water clarity, tastes, or odor, will help in identifying issues before they become serious problems.

Key Takeaways

- Brunnen schlagen involves various techniques suited for different soil types and depths.

- Site assessments and soil analysis are critical for successful drilling projects.

- Safety is paramount; equip teams with appropriate training and gear.

- Regular maintenance of equipment and wells ensures functionality and extends lifespan.

- In-depth research and modeling can help predict groundwater behavior accurately.

FAQ

1. What is the most common technique used in brunnen schlagen?

The most common techniques used in brunnen schlagen include **rotary drilling** and **percussion drilling**. Each has its applications depending on the soil type, required depth, and environmental conditions. Rotary drilling is often preferred for deeper wells while percussion drilling is effective in hard, rocky soils.

2. How do I assess a site before drilling?

Site assessment involves several steps, including conducting soil tests and hydrologic modeling. Collect soil samples for analysis, check for stability, and understand the groundwater flow patterns to determine the best location for drilling. This upfront assessment is essential to ensure a higher success rate for the project.

3. What are the main safety precautions in well drilling?

Essential safety precautions include wearing protective gear, maintaining equipment, and having an emergency plan in place. Training all personnel on safety protocols and ensuring good communication can also help reduce risks and improve site safety during the brunnen schlagen process.

4. How often should I maintain my drilled well?

It’s recommended to carry out annual maintenance checks on drilled wells. This includes testing water quality, inspecting sealing and casing, and ensuring that physical components are functioning correctly. Regular maintenance helps prevent contamination and other issues from arising.

5. What materials should I use for well casing?

Common materials for well casing are steel and PVC, with the choice often depending on local regulations and the specific groundwater conditions. Selecting quality materials and ensuring correct installation is necessary for maintaining the integrity and safety of the well over time.